Additive manufacturing, sometimes called 3D printing, is revolutionizing how materials are designed and made. Products can be manufactured through a process of successively layering materials based on an engineering model. This approach can also be used for additive repair-the process of adding back structural material lost to corrosion and wear. However, it difficult for additive manufacturers to ensure the reliability of their material without invasive testing techniques. Neutron scattering can help solve that problem, providing information about the material without destroying or damaging it.

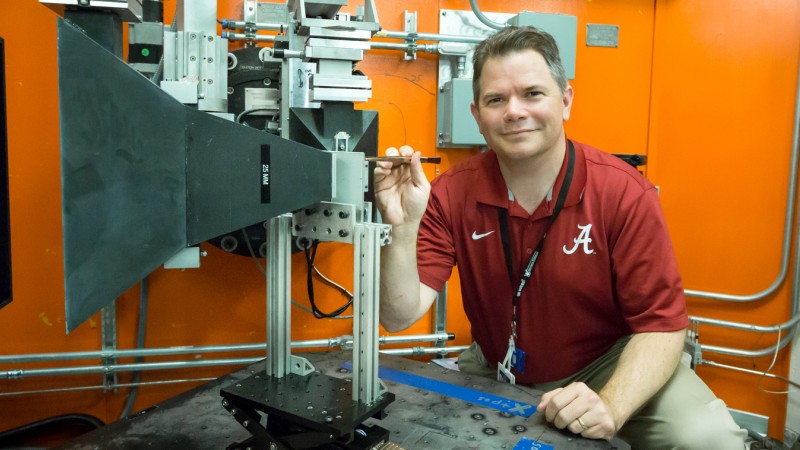

Sponsored by the Office of Naval Research, a group of researchers is using an additive manufacturing process – specifically in depositing metal powders using cold gas dynamic spraying for corrosion protection and additive repair applications. The advanced neutron scattering capabilities at ORNL are employed to assess the reliability of the repair process. Luke Brewer, Associate Professor at the University of Alabama Department of Metallurgical and Materials Engineering, is using the Neutron Residual Stress Mapping Facility, High Flux Isotope Reactor (HFIR) beam line HB-2B, to study a metal powder application that he and his colleagues at the Naval Air Systems Command and Naval Surface Warfare Center Carderock Division, are interested in using for corrosion protection and additive repair of aircraft structures. They are interested in understanding the residual stresses in the material, or stresses that remain even when the applied loads are removed.

“The cold spray metal powder coating we are studying – an aluminum-copper alloy – could be applied to aircraft or marine vessels through a super sonic velocity spray,” said Brewer. “The powder flows at two to three times the speed of sound and explosively welds when it hits the substrate.”

The level and distribution of residual stress is important in understanding the potential spallation and fatigue cracking of the coating. The HB-2B instrument is designed to use the high penetration power of neutrons to generate “maps” of the strain resulting from residual or applied stresses in bulk materials.

“We want to understand how systematic changes in powder particle microstructure change the level of residual stress in the coating, and how to predict the reliability of coatings as they experience fatigue,” said Brewer.

Brewer and his team also studied additional temperatures and pressures to gage the effect of increasing particle temperature and in-flight velocity upon the residual stresses formed.