When project managers identify new key assets needed to accomplish their objectives, the options are usually to build in-house, buy or lease, or partner to produce or acquire those assets.

Those were the choices facing the management team for the Proton Power Upgrade (PPU) project at Oak Ridge National Laboratory (ORNL). PPU will double the power capability of the Spallation Neutron Source linear accelerator, or linac, from 1.4 to 2.8 megawatts to facilitate new types of neutron science experiments and discoveries.

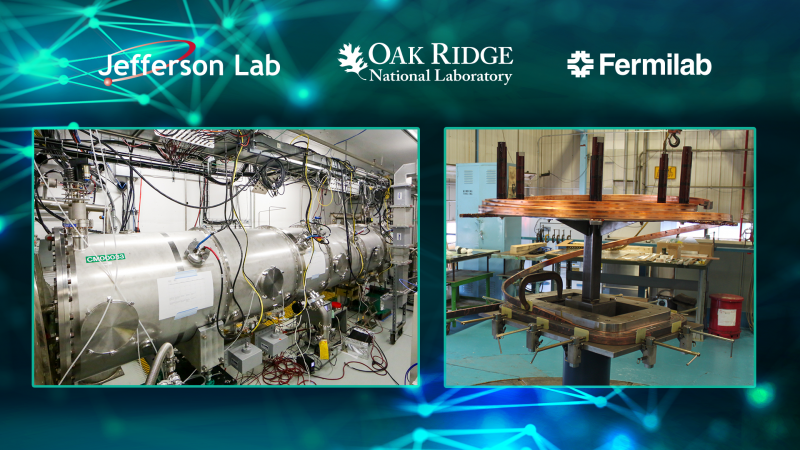

Among the largest and most critical of the PPU project’s new components are eight 11,000-pound superconducting cryomodules to accelerate the proton beam and four 14,000-pound bending magnets designed to steer and focus the proton beam inside the accelerator. Each of these multi-million dollar, custom units requires state-of-the-art planning, design and fabrication to meet the performance standards that enable world-leading research.

A cryomodule delivered from Jefferson Lab is shown in the test cave at the Spallation Neutron Source at Oak Ridge National Laboratory. Credit: ORNL/Mark Champion

“We didn’t have the in-house expertise and facilities to produce this equipment. Building in-house capabilities for just 4 magnets and 8 cryomodules would have been prohibitively expensive and taken longer than our schedule allowed,” said John Galambos, PPU project director. “Considering this expertise and fabrication capability already existed at our sister national laboratories, it made collaboration an easy choice.”

The limited number of potential suppliers allowed the PPU team to quickly narrow the list of candidates. Each was evaluated for their potential to work with ORNL in a “strategic alliance,” instead of as only a vendor. Ultimately, the team selected the Thomas Jefferson National Accelerator Facility, or Jefferson Lab, to produce the cryomodules and the Fermi National Accelerator Laboratory, or Fermilab, to fabricate the magnets.

“Collaborations and partnerships between the DOE national laboratories have long been a cornerstone that helps ensure we are leveraging the nation’s best minds and facilities for world-leading research and development,” said Ken Andersen, associate laboratory director for ORNL’s Neutron Sciences Directorate. “We are confident that Jefferson Lab’s and Fermilab’s work on the PPU project’s cryomodules and magnets will once again be of superior quality.”

Strategic partnerships – mutually beneficial arrangements

When companies and institutions with expertise in a similar field work together to develop a product, their combined experience and resources usually produce better solutions.

This was the case when ORNL and Jefferson Lab formed strategic partnerships to design and build new linac cryomodules. In the early 2000s, ORNL engaged Jefferson Lab to design and fabricate the initial 23 cryomodules for installation at the new Spallation Neutron Source. The second instance was when the team began planning the PPU upgrade, which will require seven additional cryomodules and an eighth as a spare.

Jefferson Lab’s expertise in developing the first SNS cryomodules gave the DOE facility a slight advantage during the competitive PPU partner selection process. However, it was their experience at working with ORNL in the first strategic alliance that won the contract.

“We like to think of ourselves as a repeat customer for ORNL,” said Ed Daly, the SNS-PPU senior team leader for Jefferson Lab. “A lot of our current team members also worked on the original SNS linac cryogenic and radio-frequency systems. That means we can carry that experience over to the PPU project and leverage it to help upgrade the technology on the latest versions.”

Daly explained that having two national laboratories in a strategic alliance helps the DOE better leverage the core capabilities of its facilities and scientific staffs. “I was a design engineer the first time around, so I know the cryomodules inside and out. The team at Jefferson Lab is very familiar with many of the ORNL staff and what they expect. That technical knowledge and those working relationships are why our partnership as a whole is greater than the sum of its parts. We make each other better the way we work together.”

Sharing the risks and rewards

Each of the PPU cryomodules contains superconducting radio-frequency cavities that operate at cryogenic temperatures, just 2 degrees above absolute zero (about -460 degrees Fahrenheit).

“The cavities accelerate the beam and must be precisely formed and finished during a complex series of machining, welding and chemistry steps, which is why they’re challenging assemblies to fabricate,” said Daly. “When the cavity vendor was at risk of falling behind schedule, the PPU managers asked if we could help. Our team at Jefferson Lab, having recent experience working with this particular vendor on another strategic partnership project, knew it would be some extra work and result in some added risk. We also knew it would be beneficial for our own schedule and that of the entire PPU project. So we engaged and helped the vendor finish the cavities. That’s the kind of added value you can bring to the table when you partner with the client.”

Mutual trust between partners in a strategic alliance can greatly benefit a project. This was evident when the PPU team approached Fermilab about designing and fabricating the PPU’s magnets.

“Traditional vendors are typically more demanding. They require exact specifications for each deliverable early on to estimate and quote prices,” said David Harding of the Fermilab Magnet Systems Department. “But as a strategic partner, we could be more flexible and provide conceptual designs for the PPU magnets long before ORNL had finalized their specs. Even though we knew there would be changes, our initial drawings facilitated the PPU engineers’ task of completing project feasibility studies and preliminary budgets. We could also apply our experience with accelerators to understand the real needs and propose innovative solutions.”

Fermilab will also be able to precisely measure the magnetic field in detail to allow SNS physicists to model the linac’s beam behavior. If there are any surprises, adjustments can be made to the magnets.

“Now that we're in the magnet fabrication stage, we will continue to coordinate our fabrication, measurements, and delivery with the project schedule,” said Harding. “We know from experience how long each production stage should take so we are able to provide regular and accurate status reports and forecasts.”

Fermilab lead engineer Sherry Baketz inspects a chicane magnet coil.

Fermilab lead engineer Sherry Baketz inspects a chicane magnet coil.Credit: Fermilab

The road to success is 529 miles long

Initial proof of the success of these strategic alliances occurred on March 9, 2022. That was the day a truck pulling a specially equipped flatbed trailer from Jefferson Lab carrying the first new cryomodule arrived at the SNS. The unit was delivered in perfect condition thanks to the specially designed cradle that secured it for the 9-hour, 529-mile journey from Newport News, Virginia. Workers from ORNL then needed a large crane and about three hours to carefully move the cryomodule to an indoor bay. There it was inspected, chilled with liquid helium, and subjected to high-power radio-frequency performance tests during the next few weeks.

“The cryomodule passed all of its acceptance testing at Jefferson Lab and SNS,” said Mark Champion, PPU project manager. “This high level of performance on the first cryomodule is a fantastic milestone achievement for the project and reflects the excellent working relationship between Jefferson Lab and SNS in our strategic partnership.”

The second new cryomodule was delivered on May 11. After it passes its performance testing, the PPU team will begin installing the first two units later in 2022. The first magnets from Fermilab are scheduled for delivery in 2023. PPU project completion is planned for early 2025.

The Spallation Neutron Source is a DOE Office of Science user facility. UT-Battelle LLC manages ORNL for DOE’s Office of Science. The Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, please visit https://energy.gov/science.— by Paul Boisvert