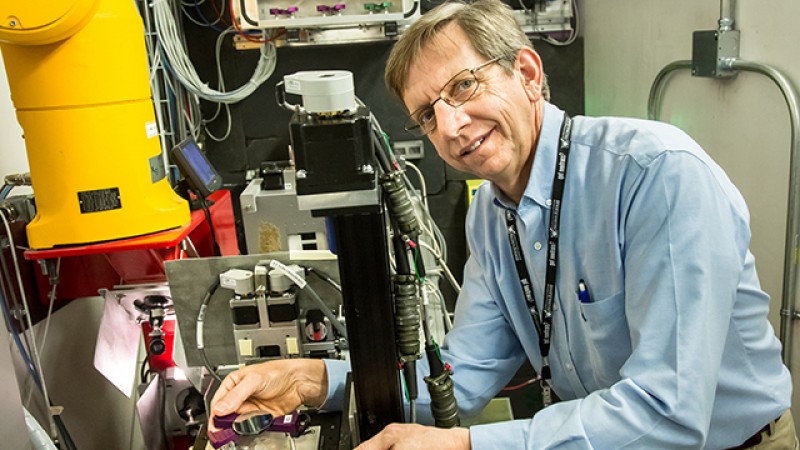

David Yarusso, a researcher with 3M, the global innovation company well known for their Post-It and Scotch brands of products, is getting down to the molecular level to study pressure sensitive adhesives at the Spallation Neutron Source. He is using the Liquids Reflectometer, SNS beam line 4B, to study how these adhesives interact with their substrates, or the thing they stick to, to ultimately improve their performance.

“It is known that rubber based adhesives have considerably better adhesion performance on polyolefin substrates than acrylic adhesives,” said Yarusso. “Our goal is to determine how much of that difference might be due to molecular interpenetration.” Yarusso explained that certain adhesives seem to work better on plastics than on metals or other surfaces. The team wants to know how much of that improved performance is based on molecular interactions between the adhesives and the substrates, specifically whether or not the adhesive penetrates the substrate, perhaps indicating some molecular compatibility that can be used to make better products.

Yarusso came to ORNL almost a year ago to prepare his samples in collaboration with the Liquids Reflectometer team: Jim Browning, John Ankner and Candice Halbert. They spread a very thin coating of an amorphous polyolefin onto a silicon wafer and characterized the thickness and roughness of that layer. They then coated various model adhesive materials as a second layer. More recently, they laminated the model adhesives to the coatings. In both cases, they used the reflection of the neutrons off of the materials of the prepared sample to determine the structure of the interface between the pressure sensitive adhesives and the amorphous polyolefin substrate, which served as a chemically similar model of the polyolefin substrates they are interested in better understanding.

“We are making the first fundamental measurements of these materials,” said Yarusso. “We typically study material performance with specific applications in mind. But in this case we’re really looking at what happens at the molecular level to understand the adhesive in a broader, more basic way. For me, it’s a nice example of how an industrial company can work with a national laboratory like Oak Ridge.”

High resolution image available: https://flic.kr/p/xT4CT3