NEWPORT NEWS, VA – One of the world’s leading neutron science facilities is souping up its already powerful particle accelerator, and the project just reached a major milestone: The final segment of that high-performance package, scratch-made at the U.S. Department of Energy’s Thomas Jefferson National Accelerator Facility, has trucked out to DOE’s Oak Ridge National Laboratory in Tennessee.

In a longstanding partnership with Oak Ridge, Jefferson Lab has been supplying particle accelerator sections, dubbed cryomodules, for the Proton Power Upgrade (PPU) of the Spallation Neutron Source. These supercooled behemoths propel particles to near the speed of light for scientific research. On Wednesday, the eighth and final one made the 529-mile trek from coastal Virginia to the Volunteer State.

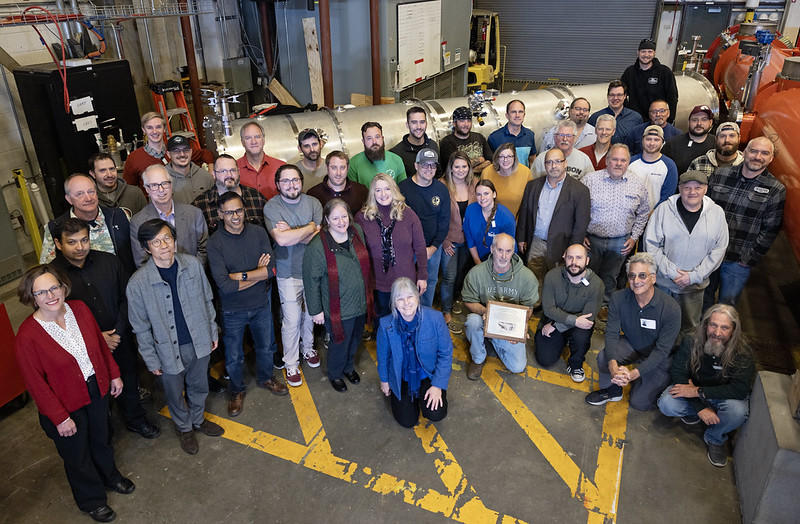

The delivery is the culmination of a seven-year, multimillion-dollar partnership that is the latest in an alliance dating back to the early 2000s. Oak Ridge had previously tapped Jefferson Lab and its world-class SRF Institute to design and build the original 23 cryomodules for the Spallation Neutron Source (SNS), which is a DOE Office of Science user facility and the world’s most powerful accelerator-based neutron science facility.

“Jefferson Lab is proud to have partnered with the SNS team on this very important project, which will help set a new standard for neutron-scattering facilities worldwide,” Lab Director Stuart Henderson said. “The strong teamwork and partnership have been central to the successful delivery of these eight cryomodules and their incorporation into SNS operations.”

Henderson has deep ties with the SNS. One of his longest career stops was at Oak Ridge, where he played key roles in the construction and eventual commissioning of the pulsed neutron source.

“I spent 10 years of my career at the SNS,” Henderson said. “It is really gratifying to see PPU come together and to have had the opportunity to be a part of it again, now from the vantage point of Jefferson Lab.”

‘Repeat customer’

The Spallation Neutron Source slams protons into a steel vessel filled with liquid mercury to produce beams of neutrons, which are used to study novel materials. These experiments lead to advances that can improve everyday products such as cellphones, car engines, batteries, drugs and bridge cables.

The Proton Power Upgrade will double the power capability of its linear accelerator, from 1.4 to 2.8 megawatts, enabling the next generation of neutron science research. This will be achieved by placing seven of the high-energy, Jefferson Lab-built cryomodules at the tail end of the accelerator, with an eighth as a spare.

DOE’s Fermi National Accelerator Laboratory, near Chicago, is another partner in the project. Fermilab fabricated four new bending magnets, each weighing 14,000 pounds, to help steer the amped-up proton beam.

In a competitive selection process for the PPU project, the lessons gained from building the first SNS cryomodules gave Jefferson Lab an edge. Retaining a core of staffers who were around for the original SNS construction also went a long way.

Among that group was Ed Daly, who served as Jefferson Lab’s senior team leader for PPU before transitioning to the private sector this past January. He was the lead design engineer during Jefferson Lab’s initial SNS construction.

“That's the beauty of having projects at the laboratories where people get to learn and grow and move into new roles,” Daly said. “You get to pay that experience forward and make the lab better at conducting these projects and being a good partner.”

World-leading expertise

Cryomodules form the backbone of many of today’s high-power particle accelerators used for scientific research, including SNS and the Continuous Electron Beam Accelerator Facility (CEBAF) at Jefferson Lab.

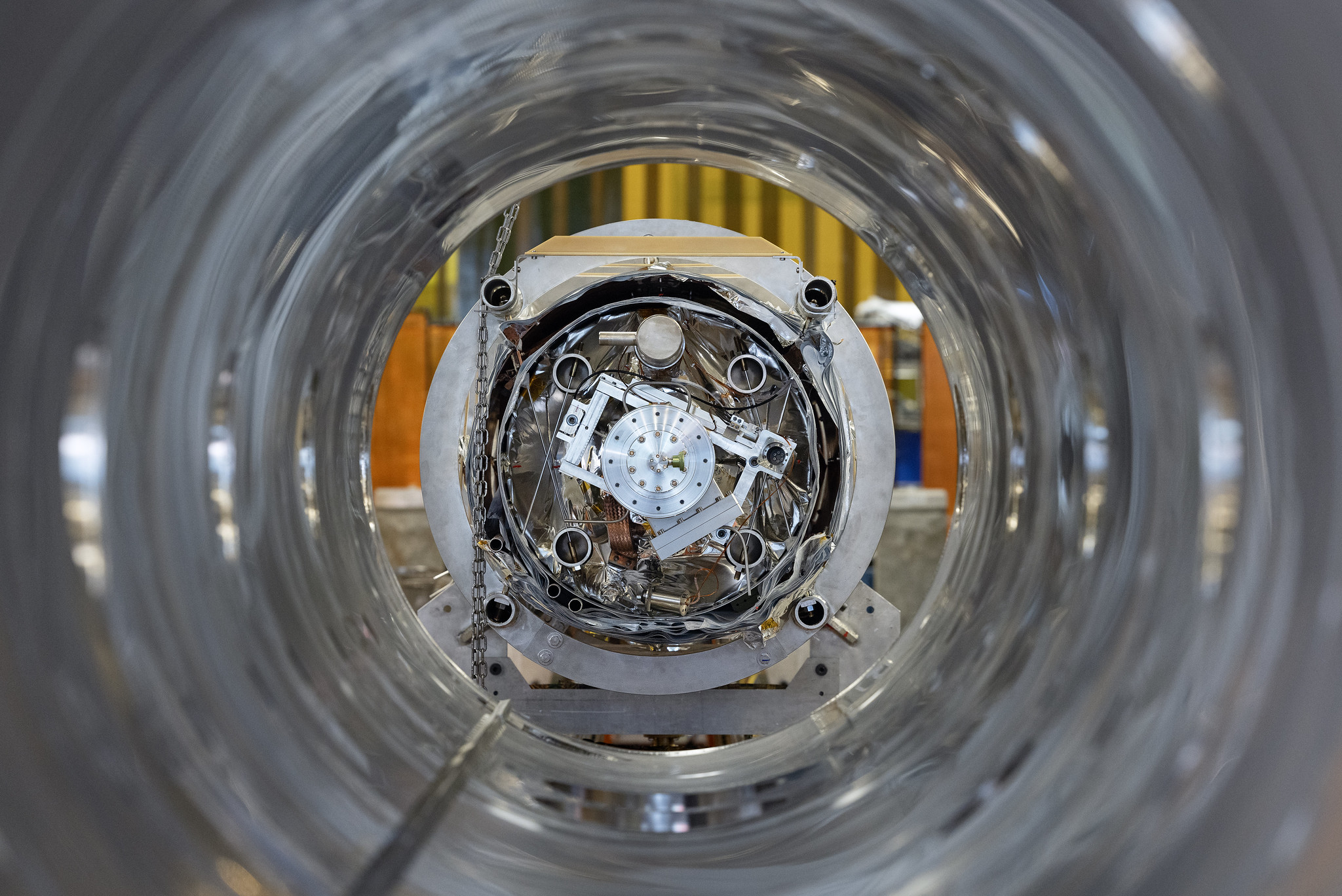

Nearly 26 feet long and weighing roughly 11,000 pounds, the PPU modules are monstrous. The outer shells of these vacuum-tight, helium-cooled tubes are fabricated from stainless steel, and they house thousands of specialized components. But the real muscle lies within the superconducting radiofrequency (SRF) cavities at the vessels’ core.

Pressed from thin sheets of ultrapure niobium and cooled to temperatures colder than deep space (-456 degrees Fahrenheit), the bulbous cells of these SRF cavities allow electric fields to resonate at high frequencies and push particles – in PPU’s case, negatively charged hydrogen atoms – to 90% of the speed of light. Each high-performing PPU cryomodule contains four of these cavities, which form a string.

“Basically, the first step is the design of the cavity and the rest of the system,” said Pashupati Dhakal, the lead research and development scientist for the PPU’s SRF cavities. “Once you know that you have a cavity, you can start building up from there.”

Jefferson Lab is a world leader in the R&D and production of SRF cavities, along with the cryomodules that house them. The lab began honing this expertise during the design and construction of CEBAF, a unique DOE Office of Science user facility supporting the research of more than 1,900 scientists worldwide, in the 1980s. CEBAF featured the very first large-scale application of cryomodules in linear accelerators and served as a proof of principle for the technology.

“One factor that sets us apart is that we are one of the longest-serving SRF facilities in the world with expertise in research, development, design, fabrication and operation of SRF cavities and cryomodules,” said Naeem Huque, Jefferson Lab’s lead engineer for the PPU cryomodules. “Some of the people running the show right now, such as our head of assembly, have been at the lab since it started.”

That institutional knowledge, and the infrastructure to handle several projects at the same time, has made Jefferson Lab a go-to source for national and international labs in need of particle accelerator components.

Juggling act

The production floor of the SRF Institute bristles with activity.

A massive overhead crane in the lab’s high-bay space swings hulking cryomodules and delicate cavity strings onto specialized workstations. Each station is tailored to the type of work performed there, forming an assembly line of sorts. The components will spend weeks to months at each stop, depending on the stage of production, before moving on to the next.

“It’s kind of like a shell game, but without the trickery,” said Ashley Mitchell, Jefferson Lab’s SRF Project Coordinator. “Everything moves, but we never lose track of the ball.”

In one area, engineers and scientists perform R&D. In another, welders and technicians carefully fuse and assemble myriad components. All the while, other specialized technicians in clean rooms follow strict protocol as they meticulously polish and test cavities to ensure the silvery niobium surfaces are blemish- and contaminant-free.

“SRF cavity technology is very unforgiving,” Daly said. “A mistake in the process and you can really reduce the performance of the cavities. So, our goal is cleanliness, cleanliness, cleanliness.”

Every move within the clean rooms is carefully choreographed to keep the air free of dust or particulates. Thanks to that intricate dance and the well-qualified technicians behind it, nearly every PPU cavity tested was free of field emission – radiation given off by particles or impurities on the niobium surface during operation. Two of those 28 cavities showed signs of field emission but were still well within specifications.

“There can't be any foreign matter inside,” Dhakal said. “The fact that we have clean cryomodules means that we were able to do that task perfectly.”

While the PPU project has reached the end of this line, the SRF Institute still has plenty of work.

Jefferson Lab is also producing another round of cryomodules for the Linac Coherent Light Source at DOE’s SLAC National Accelerator Laboratory near Stanford, California. Previously, the SRF Institute teamed up with Fermilab and several others to produce the modules for the LCLS-II upgrade, which produced its “first light” in 2023 as the world’s most powerful X-ray laser. Now, the labs are teaming up on the next upgrade, dubbed LCLS-II “High Energy” (LCLS-II-HE).

Simultaneously, Jefferson Lab is refurbishing cryomodules for its own accelerator, CEBAF, and working on designs for the Electron-Ion Collider (EIC). The EIC, which is being built at DOE’s Brookhaven National Laboratory in partnership with Jefferson Lab, will be the most powerful collider based in the United States.

“No other facility in the world is even close in terms of how many different types of cryomodules they are working at the same time,” Huque said. “Another thing that sets us apart is that we can build these things in-house, completely from scratch.”

Headed west

Headed west

From fabrication to final touches, each cryomodule can take as much as a year to produce, making each delivery a milestone of its own.

Jefferson Lab’s SRF Institute likes to mark these occasions, often months apart, by decorating the cryomodules with some seasonal flair before they are shipped out. Because this delivery was the project’s final one, the team went with a graduation theme.

To keep the festively dressed cryomodule safe during transport, crews load it onto a spring-cushioned shipping frame that dampens any shocks experienced as the truck lumbers west to Tennessee. Two drivers work in shifts to make the nine-hour, 529-mile journey safely in a single day.

“The entire project was a textbook example of how you want a collaborative government project to work,” Huque said. “I can’t imagine how it could have gone any better.”

# # #

Science Associates, LLC, manages and operates the Thomas Jefferson National Accelerator Facility, or Jefferson Lab, for the U.S. Department of Energy's Office of Science. JSA is a wholly owned subsidiary of the Southeastern Universities Research Association, Inc. (SURA).

DOE’s Office of Science is the single largest supporter of basic research in the physical sciences in the United States and is working to address some of the most pressing challenges of our time. For more information, visit https://energy.gov/science

Original story by Matt Cahill, Jefferson Lab Communications Office